Connectors, as essential components in electronic devices, play a crucial role in signal transmission and power connection. Their performance directly impacts the stability and lifespan of the device. However, long-term use or improper maintenance can lead to poor contact, oxidation corrosion, and even failure. Therefore, mastering scientific maintenance methods is crucial.

Regular cleaning is essential.

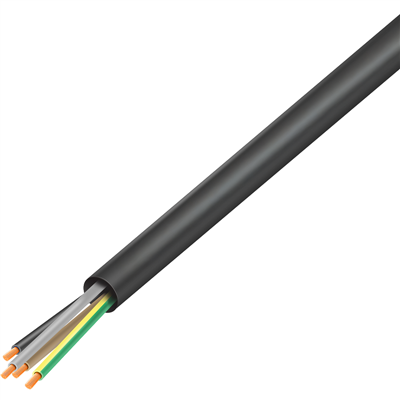

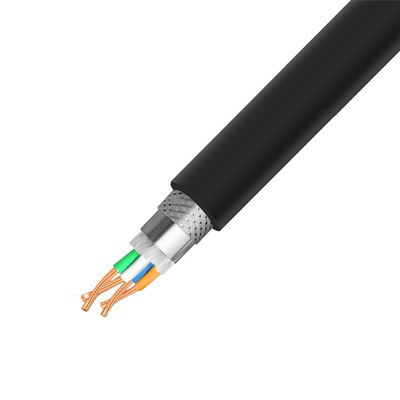

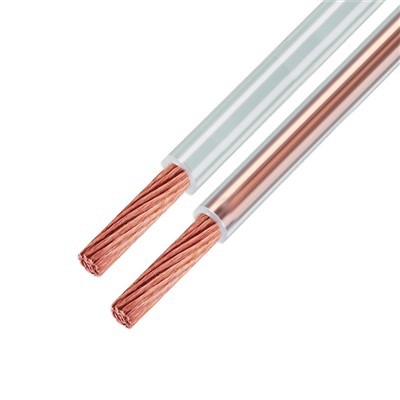

Connector surfaces are prone to accumulation of dust, oil, and oxides. These impurities increase contact resistance, causing signal attenuation and heat generation. It is recommended to gently wipe the pins and sockets with anhydrous alcohol and a soft-bristled brush to avoid scratching the metal surface. For high-precision connectors, use a specialized cleaner or compressed air to remove particles from gaps. After cleaning, thoroughly dry the connector to prevent residual liquid from causing short circuits.

Anti-corrosion and Anti-oxidation Treatment

Metal contacts are prone to rust in humid or chemical environments. It is recommended to store them in a dry, well-ventilated environment, using a moisture-proof cabinet if necessary. For exposed connectors, a small amount of anti-oxidation grease (such as silicone grease) may be applied, but be sure the grease does not affect electrical performance. Gold-plated contacts are highly corrosion-resistant, but they should still be protected from contact with corrosive substances such as strong acids and alkalis.

Proper insertion and removal extend lifespan

Rough insertion and removal can deform the pins or wear the socket. Hold the connector body and insert vertically and evenly, avoiding diagonal force. For frequent insertion and removal, it is recommended to use connectors with locking mechanisms and regularly check for loose fasteners. When not in use, dust caps can be used to reduce contamination.

Regular Inspection and Timely Replacement

Even with proper daily maintenance, connectors may still experience problems such as decreased elasticity and plating wear due to long-term use. It is recommended to inspect contact reliability every six months, focusing on looseness, discoloration, or physical damage. If poor contact or abnormal heating is observed, replace the connector promptly to prevent further problems.

Proper connector maintenance not only improves device performance but also reduces repair costs. Proper cleaning, protection, and handling practices can significantly extend connector lifespan, ensuring the long-term stable operation of electronic systems.