In modern electronic devices, power cords serve as a bridge for energy transmission. Their design not only addresses basic electrical conductivity but also carries the multifaceted missions of safety, efficiency, and sustainability. With technological advancements and the diversification of user needs, power cord design has shifted from a simple physical connection to comprehensive performance optimization, becoming a critical component of the overall reliability of electronic devices.

Safety: The First Principle of Design

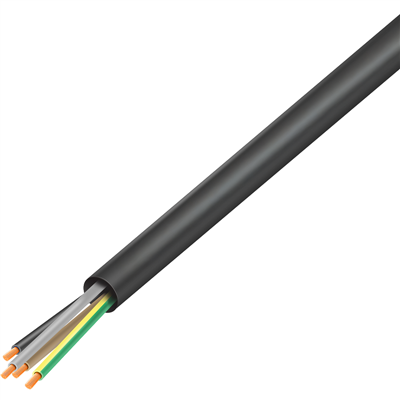

The primary design goal of power cords is to ensure safety. Efficient current transmission must be balanced with the voltage and heat resistance of the insulation material to prevent risks from short circuits, leakage, or overheating. For example, power cords for high-power devices (such as servers or industrial equipment) typically utilize a multi-layer insulation structure. The outer layer uses flame-retardant materials (such as PVC or low-smoke, halogen-free compounds), while the inner layer is made of a copper core with a precisely calculated cross-sectional area to prevent localized high temperatures caused by excessive resistance. Furthermore, anti-touch features on plugs and connectors (such as prioritizing ground contact) are also key safety features. Especially in humid or dusty environments, a protection rating (such as IP65) that meets IEC or UL standards can effectively extend service life and reduce the likelihood of accidents. Efficiency Optimization: Reducing Energy Loss and Signal Interference

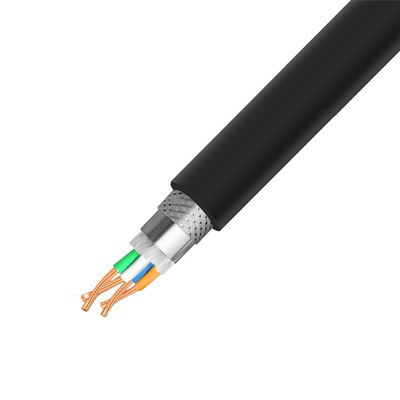

In the pursuit of efficient energy transmission, power cord design must balance conductivity and electromagnetic compatibility (EMC). High-purity copper conductors (such as oxygen-free copper) and optimized twisting structures can reduce resistance and minimize Joule heating losses during current transmission. Shielding layers (such as aluminum foil and braided mesh) can suppress high-frequency noise, preventing interference with sensitive circuits (such as audio equipment or medical devices). The recent rise in wide-bandgap semiconductor devices like gallium nitride (GaN) has further driven the development of power cords toward high-frequency, low-loss designs, requiring cables to maintain stable impedance characteristics across a wider frequency band.

Sustainability: Environmental Protection and Modular Design Trends

Faced with global resource constraints, power cord design concepts are increasingly incorporating environmental considerations. The use of recyclable materials (such as bio-based plastics or recycled copper) is increasing, while simplified construction (such as eliminating redundant packaging) is reducing carbon footprints. Modular design is another major trend. For example, laptop power adapters use interchangeable plug modules to adapt to different countries' power grid standards, reducing electronic waste and improving user experience. Furthermore, the concept of smart power cords is emerging. These integrated sensors monitor parameters like current and temperature in real time, providing users with fault warnings and extending the overall lifecycle of their devices.

Future Outlook: Intelligent and Personalized Demands

With the increasing prevalence of the Internet of Things (IoT) and electric vehicles, power cords will no longer be limited to passive transmission. Future designs may integrate microcontrollers to enable dynamic power distribution (e.g., automatically adjusting output voltage based on load) or further free themselves from the constraints of physical connections by supplementing them with wireless charging technology. At the same time, consumer demand for aesthetics and portability (e.g., flat cables or retractable designs) will drive innovation at the intersection of materials science and industrial design.

In summary, the design concept of power cords is a multi-dimensional systems engineering effort, centered on balancing functionality, safety, and environmental responsibility. Only by combining rigorous engineering thinking with forward-thinking user insights can we create high-quality power solutions that meet future challenges.