As core devices for protecting electrical systems from transient overvoltages, lightning arresters (SPDs) are closely related to their performance and the materials used. Different materials perform key functions within a SPD, such as current diversion, voltage limiting, and insulation, directly impacting the device's response speed, current-carrying capacity, and service life.

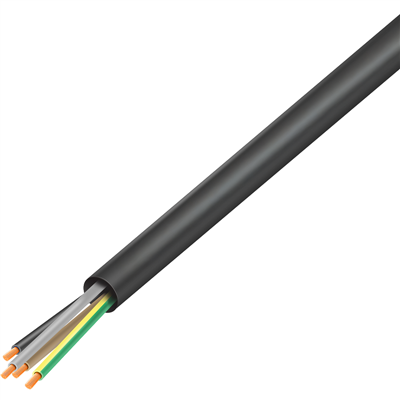

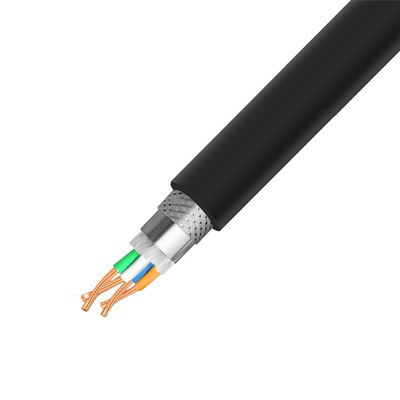

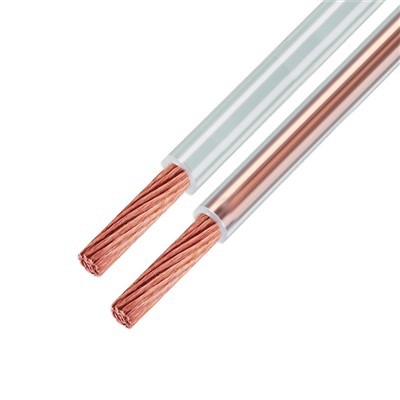

Metal Conductors: Core Shunt Components

The core components of a SPD are typically made of highly conductive metals, such as copper or aluminum. Copper is the preferred material due to its excellent conductivity and corrosion resistance, enabling it to quickly conduct lightning current to the grounding system, reducing the risk of circuit damage. Some low-cost products may use aluminum, but its low conductivity and susceptibility to oxidation require surface treatment (such as tin plating) to enhance its performance. Metal contacts and electrodes also rely on high-purity copper alloys to ensure low contact resistance and stable current-carrying capacity.

Non-Linear Resistor: Zinc Oxide Varistor Ceramics

Zinc oxide (ZnO) varistors (MOVs), key voltage-limiting components in SPDs, are sintered zinc oxide particles with small amounts of metal oxides such as bismuth and cobalt. Its nonlinear volt-ampere characteristics cause it to exhibit a high resistance at normal voltages. However, when the voltage exceeds a threshold, it rapidly conducts, limiting overvoltages to a safe range. Zinc oxide has a response time of nanoseconds and can withstand surge currents ranging from tens to hundreds of kiloamperes, making it a core material for instantaneous protection in lightning arresters.

Insulation and Encapsulation: Engineering Plastics and Silicone Rubber

The outer casing and internal isolation structure of a lightning arrester are typically made of flame-retardant engineering plastics (such as ABS and PC) or silicone rubber. These materials offer high dielectric strength, weather resistance, and UV resistance, protecting internal components from environmental corrosion. Silicone rubber is also commonly used to seal high-voltage gaps or composite insulators, where its elastic properties help buffer mechanical stress.

In addition, gas discharge tubes (GDTs), which combine inert gases (such as neon and argon) with metal electrodes, serve as primary protection elements in higher voltage scenarios.

In summary, the material selection for a lightning arrester requires a comprehensive consideration of conductivity, nonlinear characteristics, heat resistance, and environmental adaptability. Efficient and reliable overvoltage protection can be achieved through a multi-material collaborative design.