SIA, as a critical overvoltage protection device in power systems, has a significant impact on its electrical performance, mechanical strength, and service life. This article will explore key SIA molding technologies from the perspectives of material selection, injection molding, assembly processes, and quality control.

Material Selection and Pretreatment

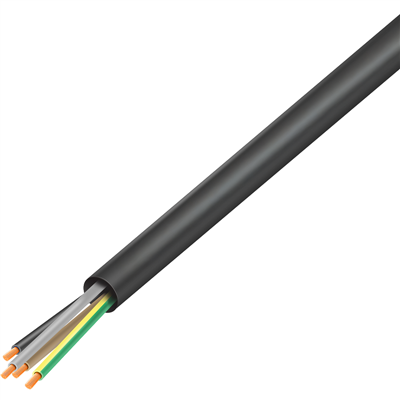

The core components of a SIA include the varistor, gas discharge tube, and housing, making material selection crucial. The housing is typically made of flame-retardant PC (polycarbonate) or ABS (acrylonitrile-butadiene-styrene) to ensure high-temperature resistance, impact resistance, and insulation properties. The varistor is made of zinc oxide (ZnO)-based ceramic, whose nonlinear volt-ampere characteristics effectively suppress transient overvoltages. Before molding, the material must be dried to prevent moisture from affecting the injection molding quality and to ensure uniform plating on the metal pins, thereby improving welding reliability.

Injection Molding Process

SIA housings are often molded using the injection molding process. Key parameters include mold temperature, injection pressure, and cooling time. The mold temperature is generally controlled between 80 and 120°C to ensure adequate plastic flow and reduce internal stress. Injection pressure must be adjusted based on material flowability. Excessive pressure can cause flash, while excessive pressure can easily lead to short-circuits. Cooling time directly impacts product dimensional stability and is typically 30 to 60 seconds, depending on wall thickness. Furthermore, air bubbles and sink marks must be avoided during the injection molding process, which can be improved by optimizing the gate design and venting system.

Assembly and Encapsulation

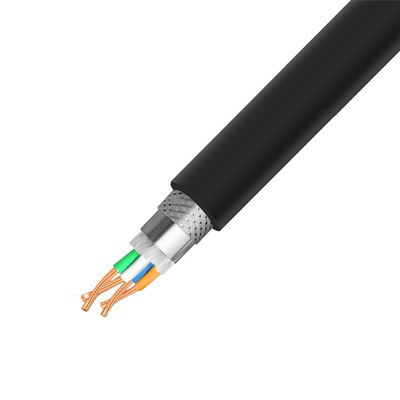

After injection molding, electronic components such as varistors and discharge tubes must be precisely assembled into the housing and encapsulated with a potting compound (such as epoxy). Potting not only enhances mechanical protection but also improves moisture resistance and insulation. Before encapsulation, components must be pre-fixed to ensure solder joints are free of cold solder joints, and assembly accuracy is verified using automated optical inspection (AOI).

Quality Control

After molding, lightning arresters undergo rigorous testing, including withstand voltage testing, insulation resistance measurement, and impact aging testing, to ensure stable operation in lightning environments. Furthermore, X-ray inspection can detect internal solder defects, further enhancing product reliability. In summary, the molding process of lightning arresters involves multidisciplinary technologies such as material science, mold design, and electronic assembly. Optimizing parameters in each link is the key to ensuring its performance.