The appearance of cable materials is one of the most important indicators for evaluating their quality and suitability. Cables are widely used in power transmission, communications, industrial control, and other fields. Their appearance not only affects their aesthetics but also directly impacts the product's mechanical properties, environmental resistance, and service life. Therefore, a thorough understanding of the appearance characteristics of cable materials is of great engineering significance.

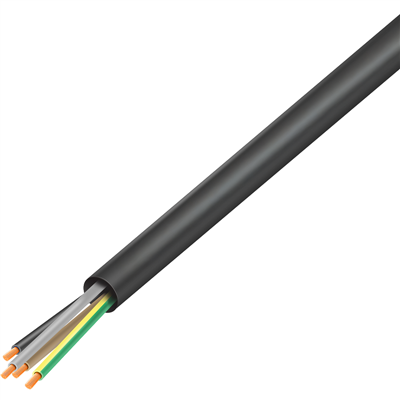

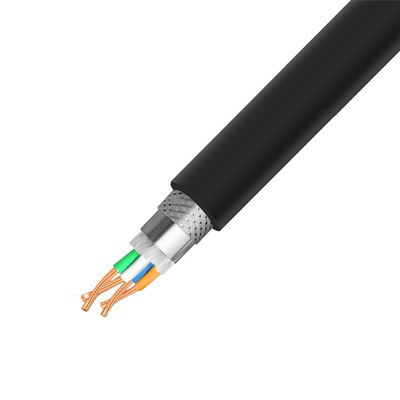

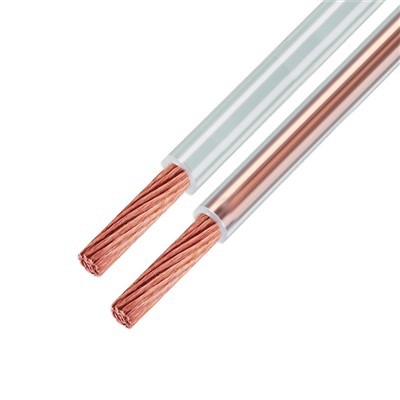

First, the conductor portion of a cable typically exhibits a metallic luster, such as a purple-red luster for copper conductors and a silvery-white luster for aluminum conductors. High-purity conductors should have a smooth, oxidation-free, and burr-free surface. Dullness, spots, or corrosion may indicate insufficient material purity or improper storage conditions. The appearance of the insulation layer is equally critical. Common insulation materials such as PVC and PE should be uniform, free of bubbles and cracks, with a consistent color and a smooth surface. Impurities, uneven thickness, or scratches in the insulation layer can lead to reduced electrical performance and even the risk of short circuits.

The sheath is the outermost protective layer of the cable, and its appearance directly affects the cable's weather resistance and mechanical protection. High-quality sheathing material should have a uniform texture, free of noticeable graininess or impurities, and a stable color with no significant color variation. Furthermore, the sheath surface should be smooth and free of dents, flattening, or distortion, as these defects can reduce the cable's tensile strength and abrasion resistance. For cables designed for special applications, such as flame-retardant or high-temperature-resistant cables, the sheath may feature specific textures or markings for easier identification and application.

In summary, the appearance of cable materials is not only an intuitive basis for quality control but also a key factor in ensuring long-term reliable operation. During the production and acceptance process, rigorous inspection of the appearance of the cable's conductor, insulation, and sheath can effectively prevent potential failures and enhance the cable's overall performance and safety.