In fields such as power transmission, communications connectivity, and industrial control, cables are like the human neural network. The cable materials-the "nerve fibers" that comprise these networks-are the core factors that determine their performance, lifespan, and safety. From the conductive metal core to the insulating outer layer, every material selection is meticulously calculated to meet the stringent requirements of different scenarios.

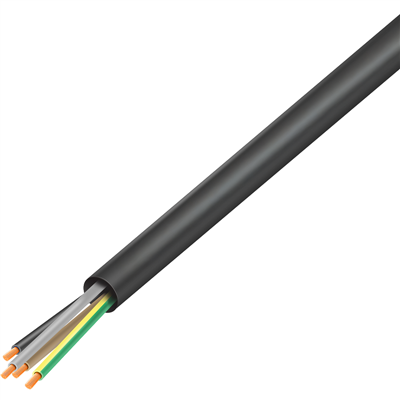

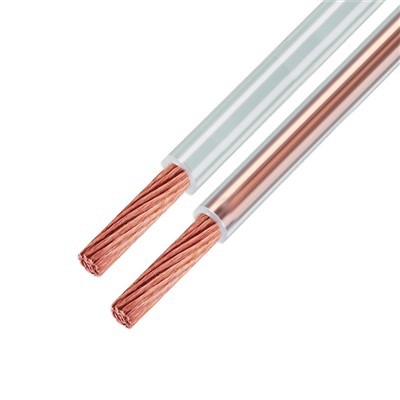

Conductor Materials: The "Highways" of Electric Current

Copper and aluminum are currently the most popular conductor materials. With a high electrical conductivity of 5.96×10⁷ S/m (Siemens per meter) and excellent fatigue resistance, copper is the preferred choice for high-voltage power transmission and precision electronic equipment. For example, ultra-high voltage cables often use multiple strands of finely twisted oxygen-free copper wire to reduce resistive heating by increasing surface area. Aluminum, with a density only 30% that of copper and a low price, is widely used in long-distance overhead transmission lines. In China's ultra-high voltage projects, individual strands of aluminum-clad steel-core aluminum stranded wire can reach lengths of several kilometers. Optimized aluminum alloy formulations have reduced the stress of its own weight on the tower by 40%. Special scenarios are driving the development of new conductors: nickel-plated copper or molybdenum alloy conductors are used in high-temperature environments, capable of withstanding continuous operating temperatures exceeding 300°C. Flexible cables in medical devices utilize silver-clad copper wire, balancing ultra-high conductivity with reliability despite repeated flexing.

Insulation: A "Chemical Armor" of Safety Protection

Breakthroughs in insulation materials are directly driving innovation in cable technology. Polyethylene (PE) remains the mainstream choice for low-voltage power cables due to its high dielectric strength (≥20kV/mm) and chemical resistance. Cross-linked polyethylene (XLPE), through chemical or physical crosslinking, increases its operating temperature from 70°C to 90°C and is widely used in building wiring.

For extreme environments, materials scientists have developed more specialized solutions: silicone rubber insulation maintains its elasticity between -60°C and 200°C, making it suitable for spacecraft wiring harnesses. Cables insulated with polyimide film can even withstand short-term operation at temperatures of 500°C, meeting the requirements of nuclear power plant emergency systems. In recent years, nanocomposite technology has incorporated microparticles such as silica and montmorillonite into a polymer matrix, increasing the breakdown field strength of the insulation layer by over 30%.

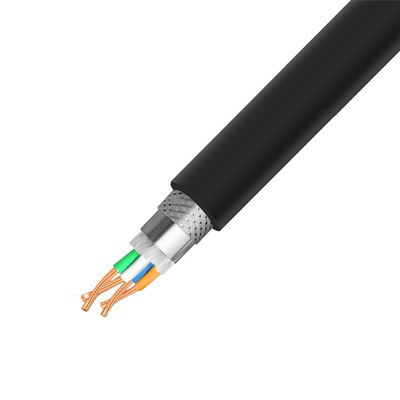

Sheathing Materials: A "Shield" Against External Aggressions

Outer sheaths not only require mechanical protection but also must withstand multiple challenges, including UV rays, ozone, and microbial attack. Polyvinyl chloride (PVC) sheathing has long dominated the low- and mid-range markets due to its low cost and flame retardancy. However, the hydrogen chloride gas released during combustion has given rise to a more environmentally friendly alternative: low-smoke, zero-halogen (LSZH) polyolefins. These materials produce only small amounts of water vapor and carbon dioxide in fires and are widely used in crowded places like subways and airports.

In marine engineering, polyurethane elastomer sheathing resists corrosion from seawater salt spray and impact from ship anchor chains. High-voltage wiring harnesses for new energy vehicles utilize thermoplastic elastomers (TPEs), which remain flexible at temperatures as low as -40°C, preventing hardening and cracking in cold regions.

Frontier Exploration: The Rise of Smart Cable Materials

With the development of the Internet of Things, smart cable materials with sensing capabilities have become a research hotspot. Fiber optic sensors embedded in the insulation layer monitor temperature and strain in real time. Conductors incorporating carbon nanotube composites can self-diagnose the location of partial discharges, providing early warning of insulation degradation. These innovations are redefining the role of cables, transforming them from "passive transmission" to "active sensing."

From copper smelting to polymer polymerization, every advancement in cable materials has pushed humanity toward more energy-efficient and reliable connections. While we enjoy 5G communications and clean energy, we should not forget these remarkable achievements in materials science, hidden within walls and buried underground-they are the true "unsung heroes" of the digital age.