Cables are core components of modern electrical and communication systems, and their performance directly impacts transmission efficiency, safety, and service life. Therefore, the selection of cable materials and optimization of manufacturing methods are crucial.

1. Cable Material Selection

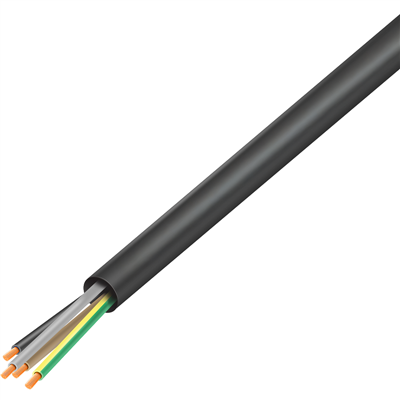

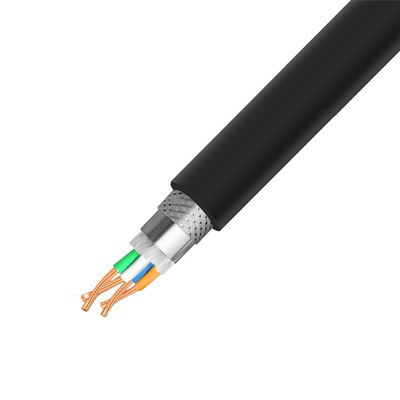

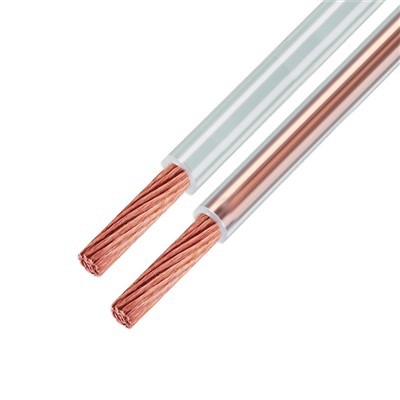

Cable materials are primarily divided into three parts: conductor, insulation, and sheath. Conductors are typically made of copper or aluminum. Copper is preferred for its excellent conductivity and mechanical strength, while aluminum is widely used for long-distance power transmission due to its light weight and low cost. Insulation materials must possess high insulation properties, heat resistance, and aging resistance. Common materials include polyethylene (PE), cross-linked polyethylene (XLPE), and polyvinyl chloride (PVC). Sheath materials must be resistant to wear, corrosion, and environmental stress cracking. Common materials include PVC, polyurethane (PU), and thermoplastic elastomers (TPE).

2. Cable Manufacturing Methods

The cable manufacturing process primarily involves four key steps: conductor processing, insulation extrusion, cabling, and sheath extrusion. First, the conductor is adjusted to the required specifications through processes such as wire drawing and annealing to ensure stable conductivity. Subsequently, an extruder is used to evenly coat the conductor surface with insulating material, forming an insulation layer. This process requires strict temperature and speed control to ensure the density of the insulation layer. Multiple insulated cores can be further twisted into a cable to enhance flexibility and interference resistance. Finally, a sheathing material is extruded over the cable structure to provide mechanical and environmental protection.

3. Future Development Trends

With the rapid development of new energy and 5G communications, cable materials are evolving towards high conductivity, high-temperature resistance, and environmental friendliness. For example, new technologies such as nanocomposite conductor materials and low-smoke, halogen-free insulation materials are emerging, driving the cable industry towards greater efficiency and safety.

In summary, the choice of cable materials and their manufacturing methods directly impact their performance and application scenarios. Continuous optimization of material formulations and process technologies is necessary to meet growing market demand.