As an essential component in electronic devices, connectors perform core functions such as current and signal transmission and mechanical fastening. From smartphones to industrial robots, automotive electronics to aerospace, connectors, despite their tiny size, are crucial for ensuring stable system operation. Their technological evolution has consistently kept pace with the demands for miniaturization, high speed, and high reliability in electronic devices.

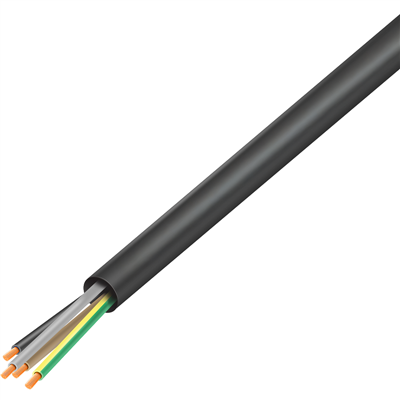

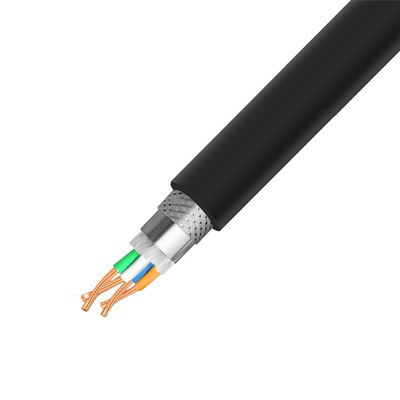

The basic structure of a connector consists of three parts: a contact, an insulator, and a housing. The contact is typically made of copper alloy with a gold or tin plating for improved conductivity and corrosion resistance; the insulator is constructed of engineering plastic to ensure electrical isolation; and the housing provides mechanical protection and electromagnetic shielding. Depending on the application scenario, connectors can be divided into dozens of types, including board-to-board, cable-to-board, power, and RF. High-speed data transmission connectors (such as USB-C and HDMI) and environmentally resistant connectors (such as military waterproof connectors) represent the cutting edge of current technology.

Technical breakthroughs in connectors are particularly significant in the fields of 5G communications and new energy vehicles. 5G base stations require high-frequency connectors to have insertion loss below 0.1dB, while electric vehicle battery management systems must carry hundreds of amperes of current. This places extreme challenges on connector current-carrying capacity and temperature control. Simultaneously, the trend toward lightweighting is driving connector miniaturization. For example, micro connectors with a 0.4mm pitch are already being used in wearable devices.

Connector reliability directly impacts system safety. International standards such as IEC 61984 and MIL-DTL-38999 strictly specify connector mechanical life (typically 10,000 mating and unmating cycles), temperature resistance (-55°C to 200°C), and vibration tolerance. The introduction of intelligent manufacturing technologies has enabled connector production precision down to the micron level, and processes such as laser welding and automated optical inspection have significantly improved product consistency.

In the future, with the explosive growth of the Internet of Things and smart devices, connectors will continue to evolve towards multifunctional integration (such as sensors and antennas), ultra-high-speed transmission (above 112Gbps), and environmentally friendly (lead-free soldering materials). This seemingly simple electronic component will continue to play a silent but critical role in supporting the seamless interconnection of the digital world.