Cables serve as the core carriers of power and signal transmission, and their material selection directly impacts system reliability, durability, and safety. Long-term engineering practice has yielded the following key insights into the properties and process adaptation of core cable materials, such as copper, aluminum, and polymer insulation.

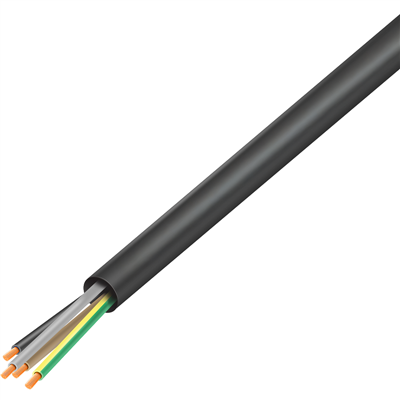

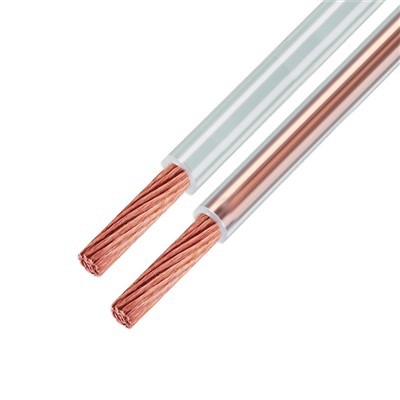

Copper conductors remain the preferred choice for medium- and high-voltage power cables due to their excellent conductivity (approximately 5.96×10⁷ S/m) and mechanical strength. In practical applications, oxygen-free copper rods must have a purity of ≥99.97% to ensure low resistance loss, while the multi-strand twisting process enhances flexibility and is suitable for frequent bending. Although aluminum conductors have a density of only 30% that of copper and are therefore less expensive, they exhibit weak creep resistance, necessitating increased cross-sectional area (typically 1.5 times that of copper) or the addition of magnesium or silicon alloys to improve connection stability. Temperature and pressure parameters, in particular, must be strictly controlled during the terminal crimping process. The choice of insulation material must be tailored to the operating environment. Polyvinyl chloride (PVC) is widely used in low-voltage wiring due to its low cost and chemical resistance, but its long-term operating temperature should not exceed 70°C. Cross-linked polyethylene (XLPE) uses a high-temperature cross-linking process to increase its temperature resistance to 90°C and offers higher electrical strength, making it the mainstream choice for medium-voltage cables. For humid or corrosive environments, a polyethylene (PE) outer sheath combined with a water-blocking filler (such as water-blocking yarn) can effectively delay water tree aging.

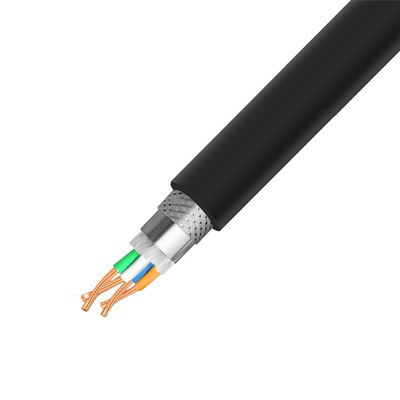

In addition, the cable shield design must not be neglected. Copper wire braid or aluminum-plastic composite tape effectively suppresses electromagnetic interference and is particularly critical in communications cables. During installation, avoid excessive bending (minimum bend radius ≥ 10 times the wire diameter) and regularly test insulation resistance and conductor continuity to extend service life.

In summary, the selection of cable materials requires a comprehensive consideration of electrical performance, mechanical properties, and environmental compatibility. System-level reliability can be achieved through precise selection and standardized construction.