Power cords are key components that connect electronic devices to power sources, and their production processes directly impact product safety, durability, and electrical performance. Standard power cord production requires multiple precision steps to ensure compliance with international electrical safety standards (such as UL and CE).

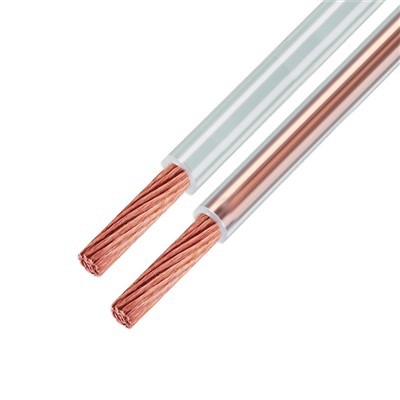

Step 1: Conductor Processing

The core of a power cord is the conductive core, typically made of copper or aluminum. Copper wire is the mainstream choice due to its excellent conductivity and ductility. First, copper rods are drawn through a continuous extruder into fine copper wires of a specified diameter. These are then twisted into multiple flexible or single rigid strands as needed. The twisting process improves the wire's flexibility and tensile strength, and controlling the lay length directly impacts current transmission efficiency.

Step 2: Insulation Extrusion

After cleaning, the conductor enters the insulation extrusion stage. Common insulation materials include PVC (polyvinyl chloride), PE (polyethylene), and XLPE (cross-linked polyethylene), with different materials suitable for different voltage levels and environmental requirements. A precision extruder evenly coats the conductor with the insulation material. The extrusion thickness must strictly meet design specifications, and the insulation integrity is tested using a spark tester.

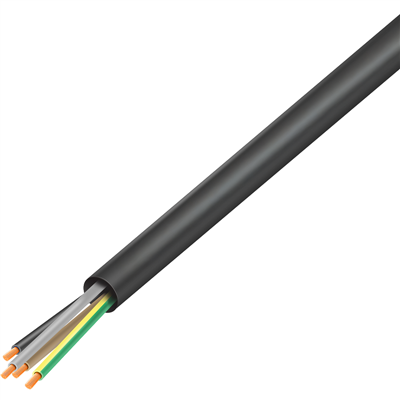

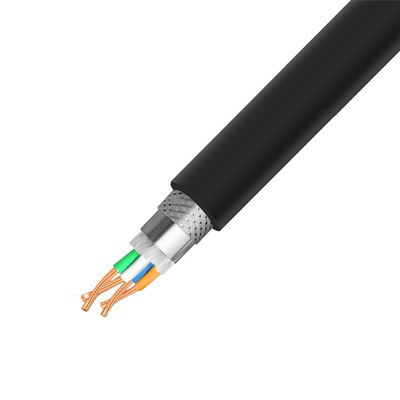

Step 3: Cabling and Shielding (Optional)

Multi-core power cables undergo a cabling process, where multiple insulated cores are twisted together according to specific rules and filled with cotton yarn or PP rope for structural stability. For power cables used in high-interference environments (such as medical equipment), an aluminum foil or braided copper shield is added to eliminate electromagnetic interference through grounding.

Step 4: Outer Jacket Forming

The final step is to coat the cable with a protective outer layer, typically made of weather-resistant PVC or rubber. The jacket extruder melts the raw material at high temperatures and simultaneously prints identification such as the model and voltage level. The finished product undergoes voltage withstand testing, aging testing, and bend testing to ensure long-term reliable operation in extreme temperature and humidity conditions.

Power cable production integrates materials science, mechanical engineering, and quality control technologies. Precision management at every step directly determines the safety performance of the end product. With the increasing popularity of new energy vehicles and smart devices, efficient and environmentally friendly production processes are becoming a key focus of industry upgrades.