As a core component of the automotive electrical system, automotive wiring's structural design and material selection directly impact vehicle performance, safety, and reliability. As the automotive industry evolves towards electrification and intelligentization, automotive wiring structures are constantly being optimized to meet higher technical requirements and market expectations.

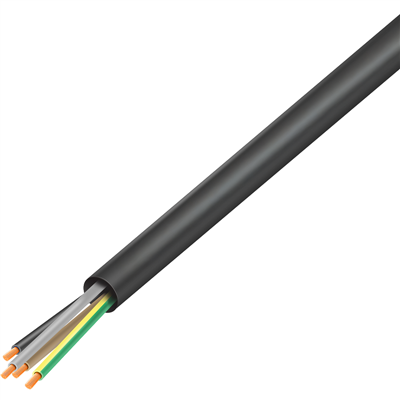

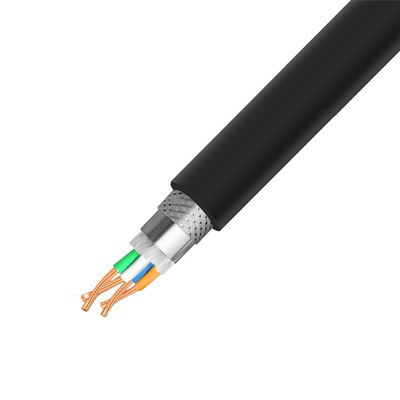

The wiring harness system of traditional fuel-powered vehicles primarily consists of conductors, connectors, protective coverings, and fixing components. Its design focuses on high-temperature resistance, interference resistance, and mechanical strength. However, the increasing popularity of new energy vehicles has posed new challenges to automotive wiring structures. High-voltage wiring harnesses must withstand higher voltages and currents, so conductor materials are typically made of higher-quality copper or aluminum alloys, while the insulation layer utilizes high-voltage and high-temperature resistant modified polypropylene or cross-linked polyethylene. Furthermore, to improve transmission efficiency, some high-end models are beginning to utilize shielded or twisted-pair wiring to reduce electromagnetic interference.

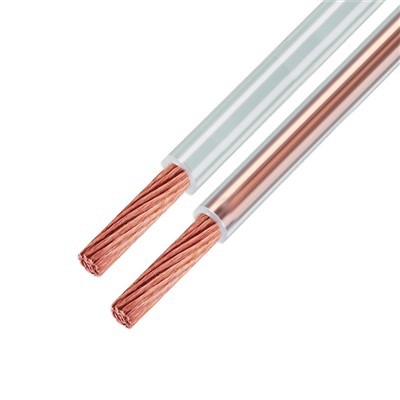

With the trend toward intelligentization, lightweight automotive wiring design has become crucial. By optimizing wire diameters, reducing redundant wiring, and employing more compact connectors, the weight of the entire vehicle wiring harness can be significantly reduced, thereby improving energy efficiency and extending driving range. At the same time, modular wiring harness structures are becoming increasingly mainstream. This design facilitates production, assembly, and maintenance, and can adapt to the flexible configuration requirements of different vehicle models.

In terms of the market, the global automotive wiring harness market continues to grow, particularly in the new energy vehicle sector, where demand for high-performance wiring harnesses is particularly strong. In the future, as autonomous driving and connected vehicle technologies mature, automotive wiring harness structures will further evolve towards high-bandwidth, low-latency technologies, such as fiber-optic communications or high-speed data buses, to meet the vehicle's real-time data processing needs.

Innovation in automotive wiring harness structures not only improves vehicle performance but also serves as a key driver of the overall automotive industry chain. Companies must closely monitor technological trends and optimize their product portfolios to meet increasingly complex market demands.