Power cords, as the critical connection between electrical equipment and power supplies, have performance that is closely related to their intended environment. Different environmental conditions place varying demands on power cord materials, construction, and protection levels. Improper selection can lead to equipment failure, safety hazards, and even fire risks. This article systematically analyzes the environmental adaptability requirements for power cords from the perspectives of temperature, humidity, mechanical stress, chemical corrosion, and electromagnetic interference, and provides selection recommendations for typical scenarios.

I. Impact of Temperature on Power Cords

The insulation and sheath materials of power cords are susceptible to physical or chemical changes at extreme temperatures. For example, ordinary PVC insulation accelerates aging in environments exceeding 70°C for extended periods, resulting in a decrease in insulation performance. At temperatures below -10°C, some materials become brittle and may crack when bent. For high-temperature environments (such as near industrial furnaces or outdoor equipment in summer), cross-linked polyethylene (XLPE) or silicone rubber insulated power cords with a temperature rating of 90°C or higher are recommended. For low-temperature environments (such as outdoor equipment in winter or cold storage), cold-resistant PVC (operating down to -25°C) or fluoroplastic insulated cables are recommended.

II. Humidity and Waterproofing Requirements

Humid environments reduce the insulation resistance of power cables, and moisture penetration can cause short circuits or corrosion of metal conductors. In dry indoor environments (such as offices and homes), standard insulated power cables are generally sufficient. However, in high-humidity areas such as bathrooms and swimming pools, waterproof cables with an IPX7 rating or higher must be used, or waterproof connectors and rubber seals must be installed for added protection. Outdoor applications (such as streetlights and communication base stations) require further consideration of rain and UV aging. Double-jacketed power cables (inner insulation + outer UV-resistant PVC or PE) are preferred, and connectors must be fully sealed.

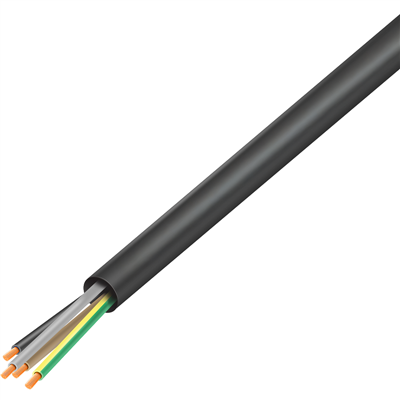

III. Mechanical Stress and Physical Protection

Power cables in mobile devices (such as factory robots and stage lighting) or in environments subject to frequent bending can be susceptible to insulation damage due to stretching, twisting, or compression. For these environments, highly flexible cables (such as multi-strand fine copper conductors with an elastic rubber jacket) should be selected, with a tensile fiber core for increased mechanical strength. For fixed installations that are subject to external impact (such as floor wiring in a workshop), it is recommended to provide physical protection using conduit, cable ducts, or wall sealants. In addition, choose heavy-duty power cables with thicker sheaths (such as heavy-duty rubber-sheathed flexible cables that comply with IEC 60227).

IV. Chemical Corrosion and Special Environments

Acidic/alkaline gases or liquids in industries like chemical and electroplating can corrode the outer sheath and conductors of power cables. For example, hydrogen sulfide environments accelerate the decomposition of rubber materials, while chloride vapors can cause brittleness in PVC sheaths. Special corrosion-resistant materials are required for these scenarios: acid-resistant power cables use fluoroplastics (such as PTFE) for insulation and sheathing, while alkali-resistant cables can use modified polyethylene (PE) or chloroprene rubber (CR). Furthermore, oily environments (such as food processing machinery and auto repair shops) require cables that resist oil expansion, and oil-resistant PVC or nitrile rubber sheaths are typically selected.

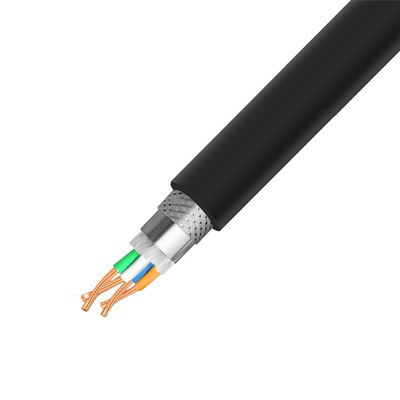

V. Electromagnetic Interference (EMI)-Sensitive Scenarios

Medical equipment, precision instruments, or communications equipment may be exposed to strong electromagnetic fields. The unshielded structure of ordinary power cables can cause signal interference or data transmission errors. In such environments, power cables with metal braid or aluminum foil shielding (such as the RVVP series) should be used, with grounding terminals to divert interference currents to the ground. For ultra-high-precision applications (such as nuclear magnetic resonance imaging and semiconductor production lines), double-shielded or fiber-optic composite power cables are also required to further enhance interference resistance.

Conclusion

The environmental suitability of power cables directly impacts the reliability and safety of electrical systems. When selecting a power cable, comprehensively evaluate the target environment's temperature range, humidity level, mechanical stress intensity, chemical exposure risk, and electromagnetic interference level, strictly adhering to international standards (such as IEC, UL, or GB/T specifications). For complex or extreme environments (such as deep-sea equipment and spacecraft), it is recommended that professional institutions conduct material compatibility testing and accelerated aging tests to ensure stable operation throughout the power cable's lifecycle.