As a critical protective device in electrical systems, lightning arresters (SAs) directly impact the safe operation of equipment. Regular maintenance is crucial to ensure reliable operation during lightning or surge events. A well-defined maintenance cycle not only extends equipment life but also effectively prevents unexpected failures.

Maintenance cycles for SPDs are typically divided into three levels: daily inspections, quarterly maintenance, and annual testing. Daily inspections primarily observe the device for any external abnormalities, such as damaged casing, loose connections, or abnormal indicator light status. A weekly quick check is recommended. Quarterly maintenance requires more in-depth inspections, including cleaning dust from the surface of the SPD, checking the reliability of the ground connection, and testing the basic parameters of its varistor or spark gap to ensure that the response time meets standards. Annual testing is a key step in comprehensively evaluating the performance of the SPD. Professional instruments are used to measure core indicators such as residual voltage and leakage current, and verify that the operating voltage is within the permitted range. For high-frequency environments (such as communication base stations and data centers), it is recommended to shorten the inspection period to six months.

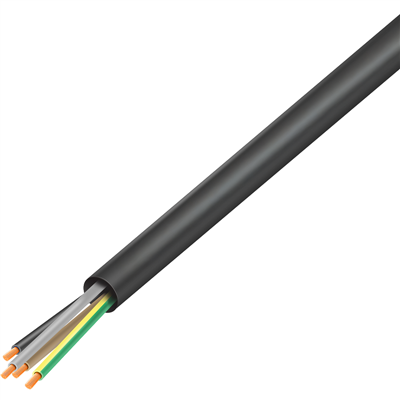

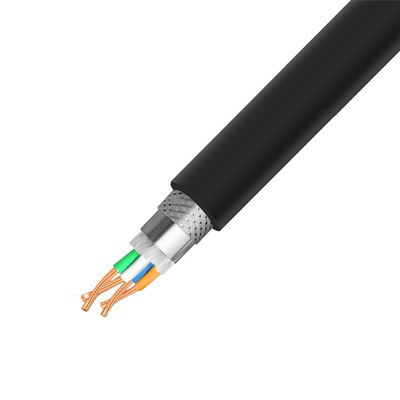

Different types of lightning arresters (such as power and signal arresters) require different maintenance priorities due to their varying application scenarios. Power arresters prioritize surge absorption capacity, while signal arresters ensure that the insulation performance of communication lines is not compromised. Furthermore, equipment in extreme climates (such as those prone to frequent thunderstorms) should undergo increased maintenance frequency to cope with more demanding operating conditions.

Neglecting lightning arrester maintenance can lead to protection failure, even causing equipment damage or safety incidents. Therefore, establishing a reasonable maintenance schedule and strictly adhering to it is essential to ensure stable power system operation. Dynamically adjusting maintenance plans based on equipment specifications, industry standards, and actual operating conditions can maximize the protection effectiveness of lightning arresters.