With the rapid development of the automotive industry, automotive wires, as a crucial component of the automotive electrical system, are seeing their scope of application and technical requirements continuously increase. They are primarily used to connect various electrical devices within the vehicle, such as the engine control system, lighting system, airbags, and in-car entertainment systems, ensuring efficient transmission of power and signals, thereby ensuring proper vehicle operation and driving safety.

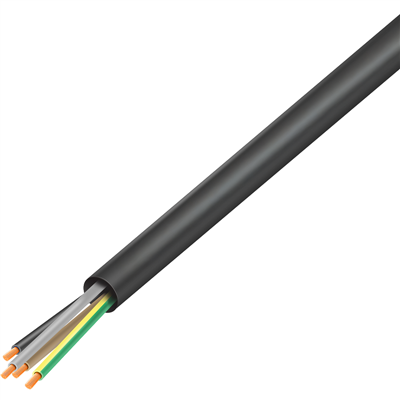

In traditional fuel-powered vehicles, automotive wires are primarily used for power distribution and signal transmission. Their core functions include providing stable power to the engine, ignition system, and fuel injection system. They also carry out signal transmission between sensors and control units, ensuring coordinated operation of various vehicle components. In recent years, with the rise of new energy vehicles, the application scenarios of automotive wires have further expanded. The demand for high-voltage wiring harnesses in electric and hybrid vehicles has increased significantly. These high-voltage wiring harnesses must withstand higher voltages and currents while possessing excellent insulation and high-temperature resistance to meet the power transmission requirements of core components such as battery management systems and motor drive systems.

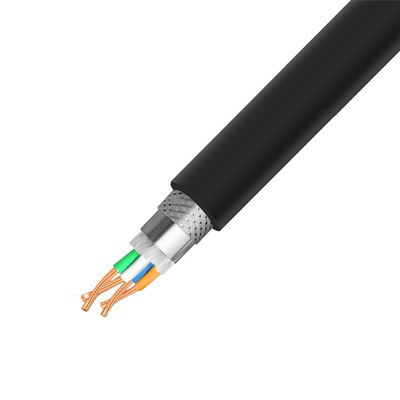

Furthermore, the rapid development of intelligent and autonomous driving technologies has also placed higher demands on automotive wires. Modern vehicles are equipped with numerous sensors, cameras, and computing units, and the data transmission between these devices requires high-speed, stable wiring harnesses. Therefore, automotive wiring must not only provide basic electrical conductivity but also meet requirements such as lightweight, electromagnetic interference resistance, and environmental aging resistance to adapt to the complex and ever-changing automotive operating environment.

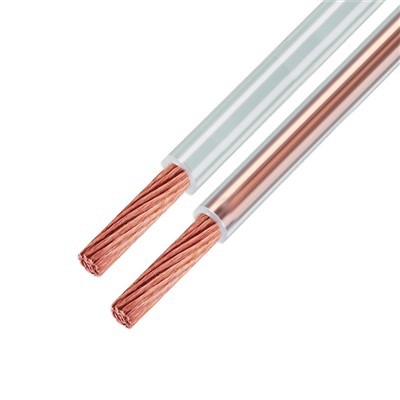

In the global automotive supply chain, the quality and reliability of automotive wiring directly impact the performance and safety of the entire vehicle. Therefore, automotive wiring manufacturers are continuously optimizing material selection and production processes, using highly conductive copper and high-performance insulation materials, and meeting rigorous testing standards to ensure their products meet the stringent requirements of the international automotive industry. In the future, as the trend toward electrification and intelligent vehicles continues to advance, the application of automotive wiring will become even more extensive, and the technology will become more advanced, providing solid support for the innovative development of the automotive industry.