INTRODUCTION

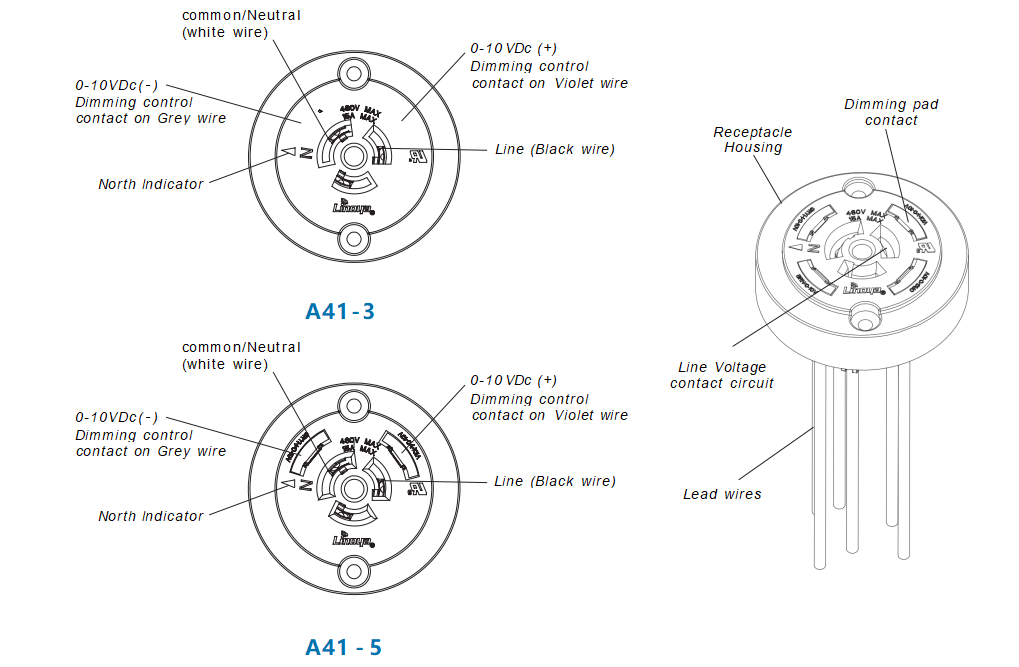

This specification covers the requirements for application of ANSI C136.41-2013(ANSI C136.10-2010). Dimming Receptacles are typically used for roadway and area lighting. All contacts are pre-installed into the receptacle housing and pre-crimped with 305 mm(12.0 in.)lead-wire,with 14 AWG stranded wire used on the three line voltag AC circuits and 18 AWG wire used on the four signal dimming control voltage DC circuits.Receptacle assemblies are available with -40-70° C.Receptacle assemblies are also available with either 2 or 4 dimming control pad-style contacts.

A41-3/5/7 SPEC-V311/2017

|

Copyright O2016-2018 by Linoya Electronic. ll rights reserved Linoya Electronicand Linoya(logo)are trademarks. kfwushu.com |

Linoya Electronics Technology co.,Ltd |

South San Francisco,CA94080 US Tel:415.366.6478 Fax.650.873.3348 |

|

|

Dongguan City,China Tel:86-0769-85550688 Fax:86-0769-85550398 |

Shenzhen City,China Tel:86-0755-29518888 Fax:86-0755-29518366 |

||

NOTE

AII numericaI vaIues are in metric units [with U.S. customary units in brackets] . Dimensions are in miIIimeters. UnIess otherwise specified, dimensions have a toIerance of ±0.13 mm and angIes have a toIerance of ±2°.

Figures and iIIustrations are for identification onIy and are not drawn to scaIe .

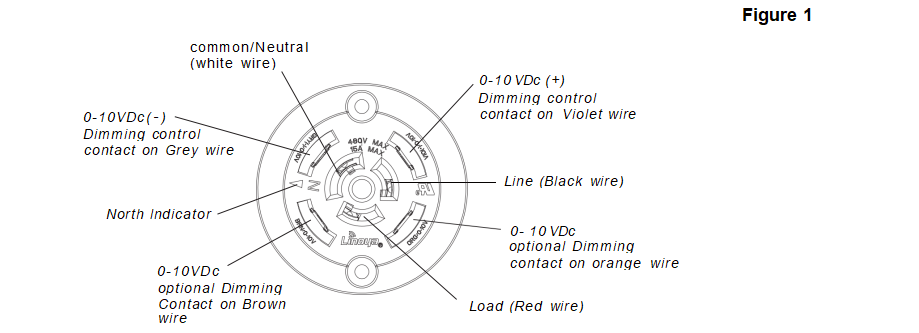

PIease use the terminoIogy provided in this specification to faciIitate inquiries for information. Basic terms and features of this product are provided in Figure 1 .

REFERENCE MATERIAL

2.1.Revision Summary

Initial release of application specification

2.2.Customer Assistance

Reference Product Base Part Number A41-3/5/7 are representative of the ANSI C136.41-200X

Dimming Receptacles. Use of these numbers will identify the product line and help you to obtain

product and tooling information.Such information can be obtained through a local linoya

Representative, by visiting our website at kfwushu.com,or by calling PRODUCT INFORMATION or the TOOLING ASSISTANCE CENTER at the numbers at the bottom of page.

2.3.Drawings

Customer Drawings for product part numbers are available from the service network.If there is a conflict between the information contained in the Customer Drawings and this specification or with any other technical documentation supplied,the information contained in the Customer Drawings takes priority.

2.4.Specifications

Product Specification A41-3/5/7 provides product performance and test information for the ANSI C136.41-2013 Dimming Receptacle.

REQUIREMENTS

3.1.Safety

Perform all wiring of receptacle with power turned OFF.

3.2.Limitations

The connectors are designed to operate in a temperature range of -40℃ to 85℃[-40°F to 185°F].

3.3.Material

The housing is made of UL94V-0 rated thermoplastic.The line voltage contacts are made of

phosphorous bronze plated overall with tin.Dimming pad contacts are made of brass with gold plating in contact pad area,tin plated in wire crimp area with nickel under-plate on entire contact.

3.4.Storage

A.UItraviolet Light

Prolonged exposure to ultraviolet light may deteriorate the chemical composition used in the

product material.

B.Shelf Life

The product should remain in the shipping containers until ready for use to prevent deformation to components.The product should be used on a first in,first out basis to avoid storage

contamination that could adversely affect performance.

C.Chemical Exposure

Do not store product near any chemical listed below as they may cause stress corrosion cracking in the material.

Alkalies Ammonia Citrates Phosphates Citrates Sulfur Compounds

Amines Carbonates Nitrites Sulfur Nitrites Tartrates

3.5.Handling

The receptacle assembly is supplied with a mating face cap to provide protection during shipping. Dimming contact pads are lubricated with an electrical contact lubricant;therefore after removal of the protective cap,avoid contact with the dimming contact pads which could remove the

electrical contact lubricant.

3.6.Receptacle Mounting

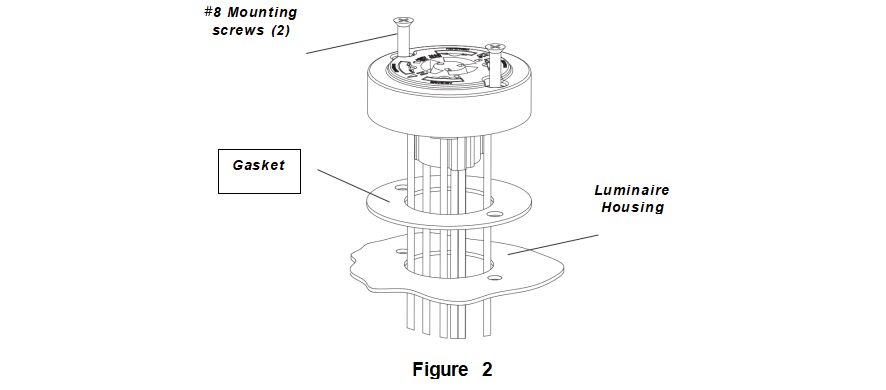

A.Mounting

A flat surface shall be provided on luminaire housing to mount receptacle assembly.To provide

water-tight mounting,it is highly recommended that a gasket(not provided with receptacle

assembly)be used to seal surfaces between receptacle assembly and luminaire housing.The

receptacle housing has two mounting holes which accept#8 size flat-head recessed screws.

Screws of the appropriate length and type must be determined by the luminaire manufacturer.

Depending on the type of gasket and mounting screws used,it is the responsibility of the installer to determine the mounting screw torque to ensure a rain-tight gasketed seal between the receptacle and luminaire housing. See Figure 2.

B.Mounting Hole Pattern

The recommended mounting hole pattern is shown in Figure 3.

Recommended

C.Mounting Location and Orientation

Locate the receptacle where artificial light cannot fall on the mating photocell causing it to turn off or cycle (on and off) at night.If possible,orient the receptacle so the North indicator points North.

D.Workmanship

The housing must not be damaged in any way.There shall be no nicked wire insulation.

3.7.Wire Connections and Diagram

A.Wire Connections

The receptacle wires must be appropriately spliced with the correct line voltage power or dimming signal source.When splicing lead wires with crimp-style splices,wire nuts,etc.,ensure the proper size splicing connector per the manufacturers' recommendation is being used.

DANGER

Extreme caution must be taken to ensure that power is OFF prior to disconnecting or connecting any wires to prevent electrical shock.

NOTE

All wire connections must be electrically insulated.

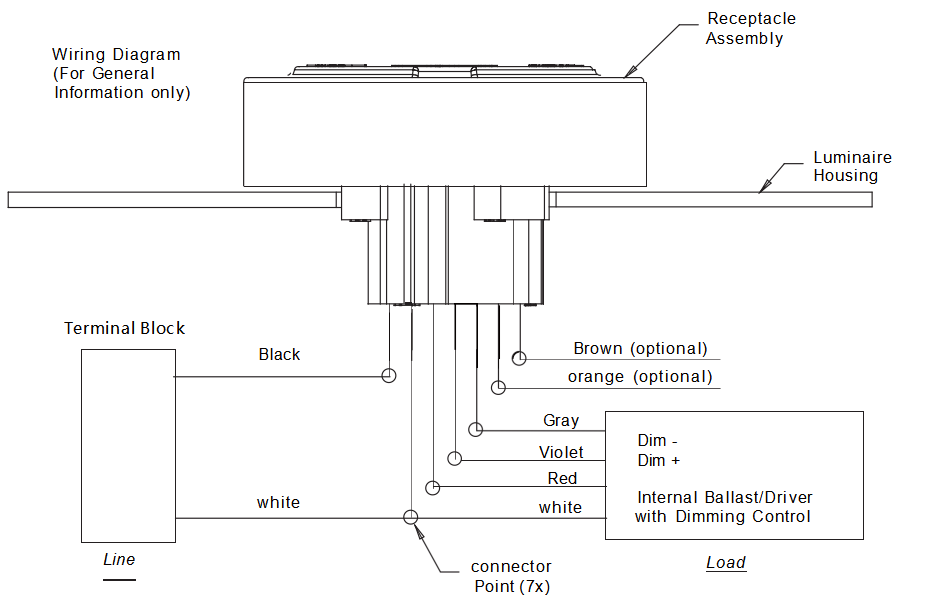

B.Wiring Diagram

The receptacle wires must be appropriately spliced with the correct line voltage power or dimming signal source.Refer to the wiring diagram example shown in Figure 4.Wiring diagram shown is for general information only. Luminaire manufacturer must determine wiring diagram based upon their ballast/driver with dimming control components.

Wires:Double PVC insulated Wire

Power:14#Black/White/Red

Signal:18#Violet/Gray/Brown/Orange

3.8.Strain Relief

It is recommended that a means be provided to support the wire bundle extending away from the receptacle assembly to prevent inadvertent application of high force to the wire bundle from

transmitting into the wire/connector interface.The suggested strain relief method is to use a cable tie and anchor mounted inside the luminaire.

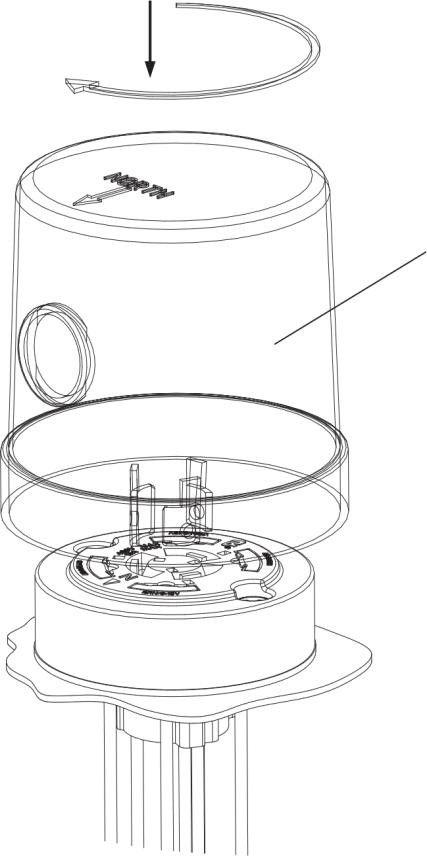

3.9.Mating and Un-mating Photocell to Receptacle

Align photocell blades with receptacle power contact circuits.Note that the neutral photocell blade is larger than the line and load blades,providing mating polarization.After properly aligning the

blades to the receptacle power contact circuits,push downward until the photocell is bottomed on the receptacle's mating surface,slightly compressing gasket of the photocell.Then complete

mating by twisting the photocell in a clockwise direction.The photocell will lock into position. To un-mate,reverse the aforementioned mating process.Reference Figure 5.

Push Downward

Twist clocKwise to Lock

3.10. Replacement and Repair

The contacts and housings are not repairable.DO NOT use an assembly with damaged or defective contacts and/or housings.If damaged,replace the receptacle assembly with a new one.

4.QUALIFICATIONS

ANSI C136.41-2013 Dimming Receptacles are Component Recognized by Underwriters Laboratories,

Inc. in File E66375,Volume 5,and have been Investigated to CSA International by UL.

5.TOOLING

No special tooling is require for the installation of this product line.

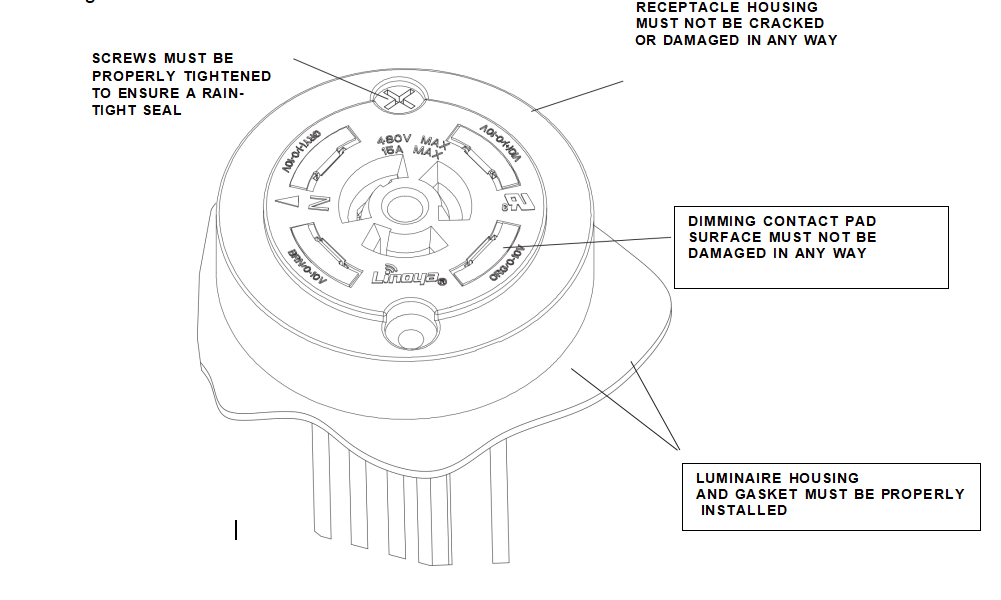

6.VISUAL AID

The illustration below shows a typical application of ANSI C136.41-200X Dimming Receptacles. This illustration should be used by production personnel to ensure a correctly applied product. Applications which DO NOT appear correct should be inspected using the information in the

preceding pages of this specification and in the instructional material shipped with the product or tooling.